An Overview¶

The Next Generation Smart Factory (NGSF) setup targets the industrial segment and incorporates hardware and software technology advances from Intel® in the design and implementation.

In a modern industrial scenario, a typical resource-saving model uses a powerful computer to control several machines, while the status of the applications and production line is inspected for production failures. This powerful machine is also responsible for quality control, utilizing artificial intelligence in the edge, and gathering data for preventive maintenance.

These tasks involve real-time processing, deterministic communication, inference, orchestration, and virtualization, among others, in a constant evolution. The NGSF setup helps complete all these tasks and displays information for the systems as they are run and provide measurable feedback that can be used for quality-of-service evaluation.

NGSF requires precision and speed, which drove the decision to choose a deterministic industrial communication protocol. The OPC UA PubSub was selected over Time Sensitive Networking (TSN) as it is available as an open source library via Open62451.

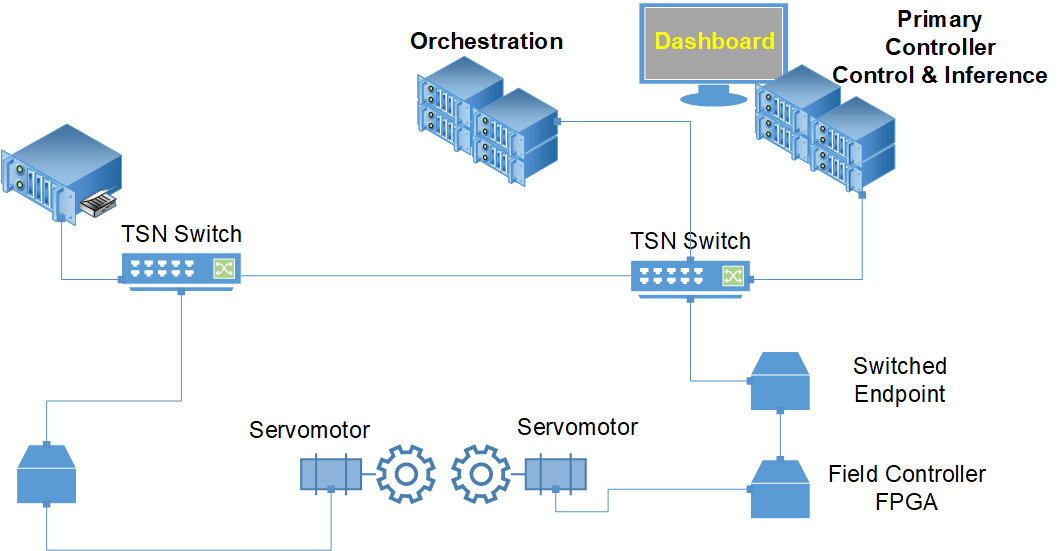

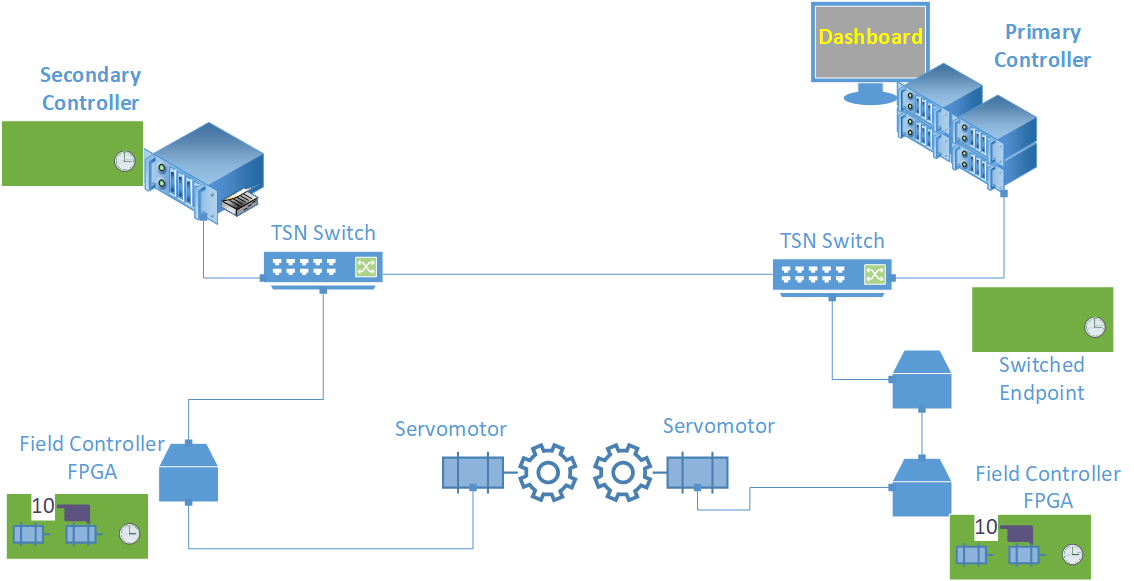

The NGSF setup, shown in the following figure, is composed of Industrial PCs used as Primary and Secondary Controllers, TSN switches, regular network switches, and FPGAs used as switched endpoints or field controllers for servomotors. To allow a flexible setup, the TSN switches are placed strategically, enabling the exchange of media used for communication. Communication between the two TSN switches can be done using 5G, WiFi, or a network cable, however the figure shows radio waves to represent any media.

Note: The connection between the TSN switches is shown with radio waves for simplicity, however, any connection, such as direct wired connection or wireless (5G or WiFi) can be used.

In the setup, the Primary Controller is responsible for deterministic communication, and for showing the status or measurements of the whole system and performing inference on the edge.

To showcase the importance and functionality of deterministic communication, the two servomotors are synchronized by OPC UA messages published from the Primary Controller, TSN switches, FPGA controllers, and FPGA switched endpoints, all of which use Intel technology.

In addition to controlling the servomotors, the NGSF setup measures key performance indicators (KPIs), such as quality of synchronization and end-to-end latency, among others. For a comprehensive list of KPIs, refer to Message Architecture.

Applications communicate using the OPC UA PubSub specification over TSN using the Open62541 stack.

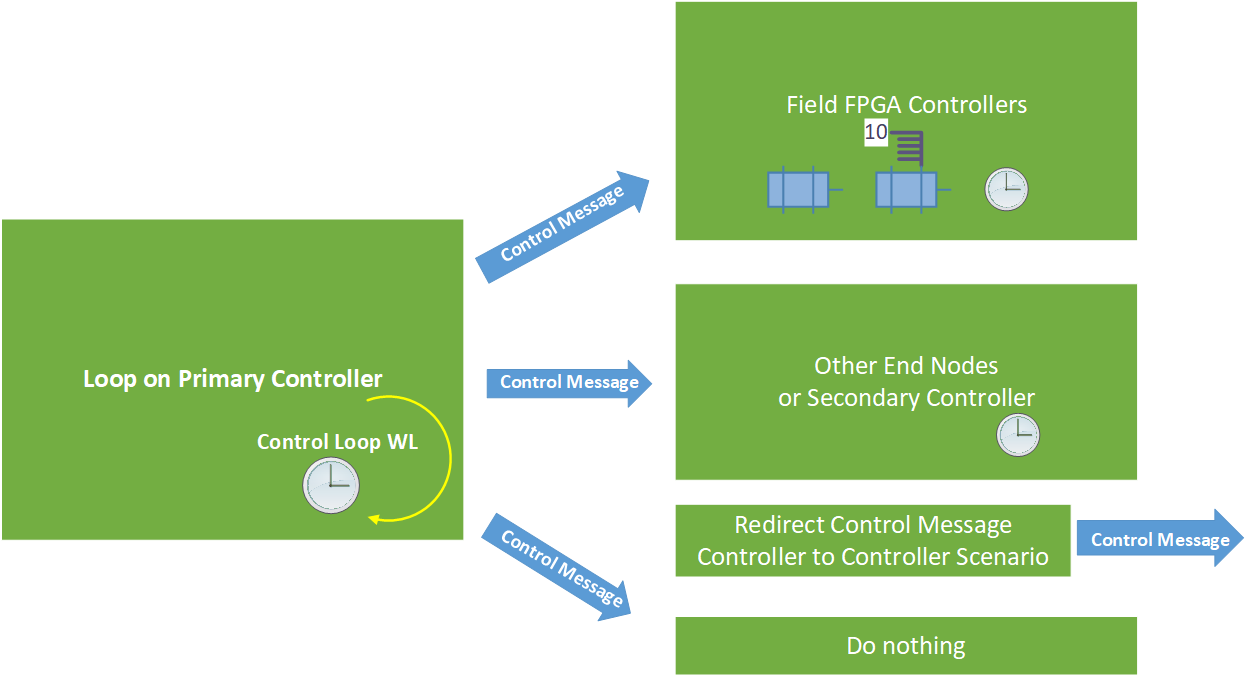

Control messages can generate several actions on an end node, as shown in the following figure, depending on the implementation of the application running on the node. The application can perform any of the following tasks or do nothing:

Control the servomotors and perform measurements

Perform measurements

Relay controllers

The flexible setup allows you to control the motors or execute measurements using the same application, which enables you to assemble the system step-by-step, either the full NGSF setup or a topology for taking measurements. The following figure shows the actions performed by each end node. For detailed steps on assembling the system from a simple setup with two end nodes, refer to Building NGSF.

To summarize, NGSF is an expandable setup with a real industrial use case as its foundation, which:

Demonstrates the synchrony of two servomotors

Allows measurement of KPIs

Fosters the use of adjacent technologies, such as orchestration, virtualization, and so on that are important for the Industrial segment